If our previous posts about the preparation of coffee have seemed a bit piecemeal or out of order, hopefully this master-post will help put things in perspective. During our last few days on the farm, we got to walk through the whole process--minus picking of course.

First things first: here is the center of the processing operation. The top level is the drying deck, where freshly washed coffee beans are spread out to dry. Moisture levels have to be checked regularly in order to catch the beans at the proper...dryness. Beneath the drying deck is where Mollie and I spent most of our time handling coffee. I'm not very tall (5' 10" if I'm trying to impress someone), but I had to hunch a bit while working in some areas of this space. It houses the pulping station, milling machine, sorting table, and roaster--with which you will soon become very familiar.

Here is the pulping station. As you'll see below, we dump the cherry into the hopper, the red skin is stripped off and a slimey whiteish bean is dropped into the large basin underneath. These beans will sit in water overnight to ferment: a chemical reaction takes place that will actually make them hot enough to melt away the slimey membrane! After they are washed the next day, they are laid out on the drying deck--on the level above this room, if you remember from the first image in this post.

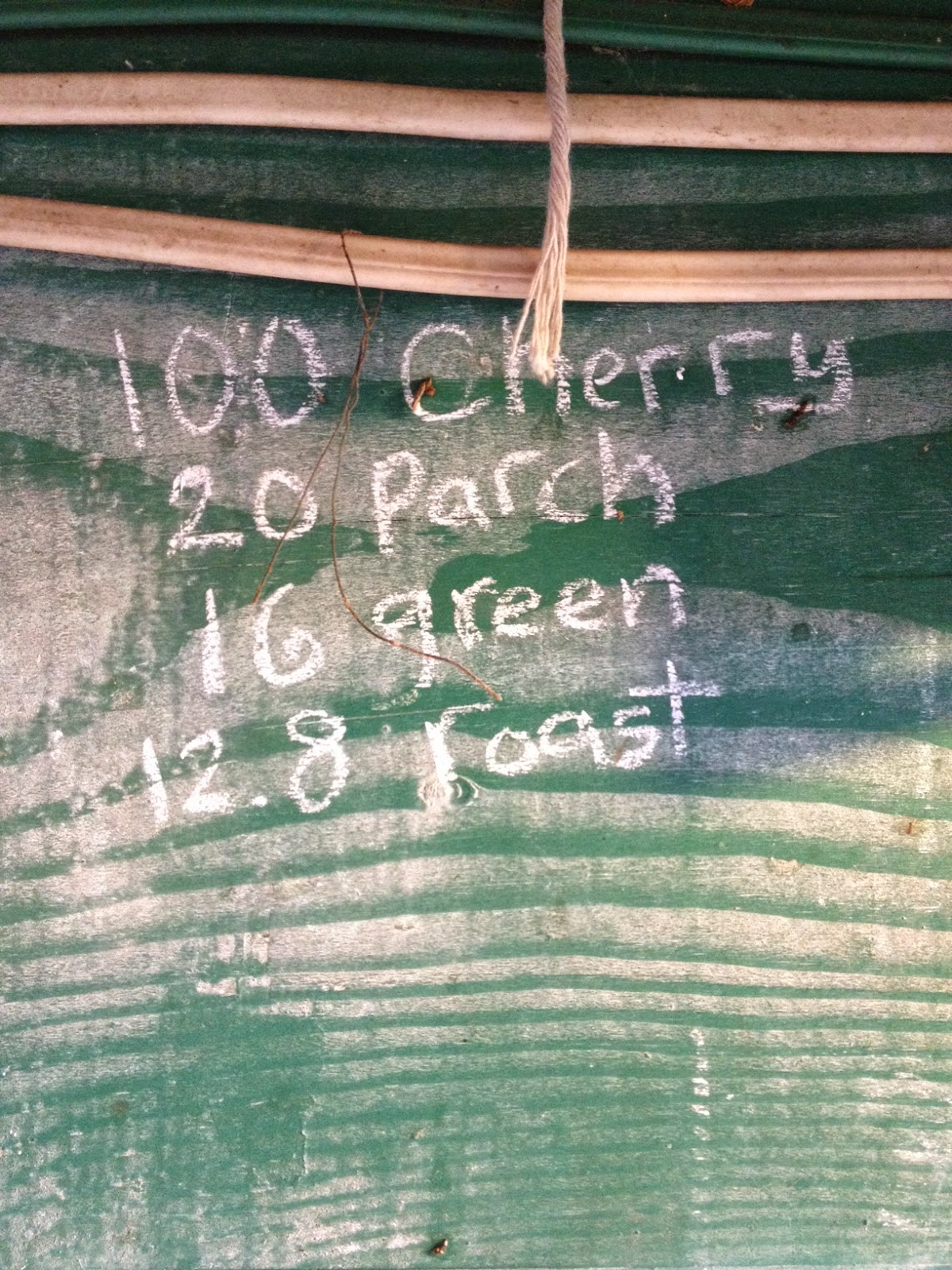

Once the beans are dry, they appear in their "parchment" form and are sent to the milling machine. Passing through a screw mechanism, the parchment is ground off and the green bean is revealed. Every bean passes through this machine no fewer than two times.

Here is Mollie working at the sorting table. Before green beans can be roasted, we have to pan out the junk fragments and the peaberry. You'll see above three sorting screens: the first is small enough to let only broken beans through, and the second and third draw out the peaberry. If you remember from an earlier post, peaberry is the smaller, rounder bean with more concentrated flavor that sells for a good bit more than regular beans.

After sorting, we are finally ready to roast. The roaster is basically a glorified blow dryer that keeps the beans moving in a vertical fountain over the heater. While roasting, we have to constantly control the fountain by reducing the blower speed to adapt to the rapidly decreasing weight of the beans.

In the videos below, we are working on a medium-dark roast, which was by far the most exhiliarating roasting experience. Imagine your standard coffee bean: it is divided into two halves. During roasting, each half pops(!) at a different temperature.

For a medium roast, we get through the first crack and then continue roasting until we reach a predetermined temperature and then dump the coffee into the cooler.

But for a medium-dark roast we wait until the second pop just begins and then dump. Timing is everything, ensuring the beans continue and finish their second pop once in the cooler.

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)